The extrusion industry is always changing for the better. One of the more important innovations in the world of extrusion is the continued improvement of blown film extrusion, and its ability to provide cost-effective, reliable results with minimal scrap, and better overall efficiency. In this blog post, we’ll discuss blown film extrusion, why it’s replacing cast film, and why companies in the extrusion industry may wish to upgrade their lines to utilize blown film equipment. Let’s get started now.

The Benefits of Blown Film Extrusion Vs. Cast Film

Primarily, there are 3 major benefits that blown film extrusion offers, compared to cast film. Let’s discuss each one in turn now.

- Cost – Blown film extrusion equipment usually costs about half as much as equipment for cast lines. Not only that, but it also does not take as long to set up blown film extrusion equipment for production runs and blown film produces much less scrap, compared to cast film.

- Flexibility – Any single die on a blown film line can run multiple sizes and widths without requiring much trimming. This leads to much higher product flexibility when it comes to blown film processing.

While cast lines can deliver higher film output and run better thickness tolerances, die size limitations can mean long setup times and production runs, so they are hard to manage in a multi-product environment.

- Durability of film – The process of blown film extrusion results in a better mechanical structure, because the film is drawn both in the direction of the machine, and transversely. Multidirectional thinning and stretching are inherent in the process, resulting in a stronger, more durable product.

The Value of Blown Film Extrusion Upgrades

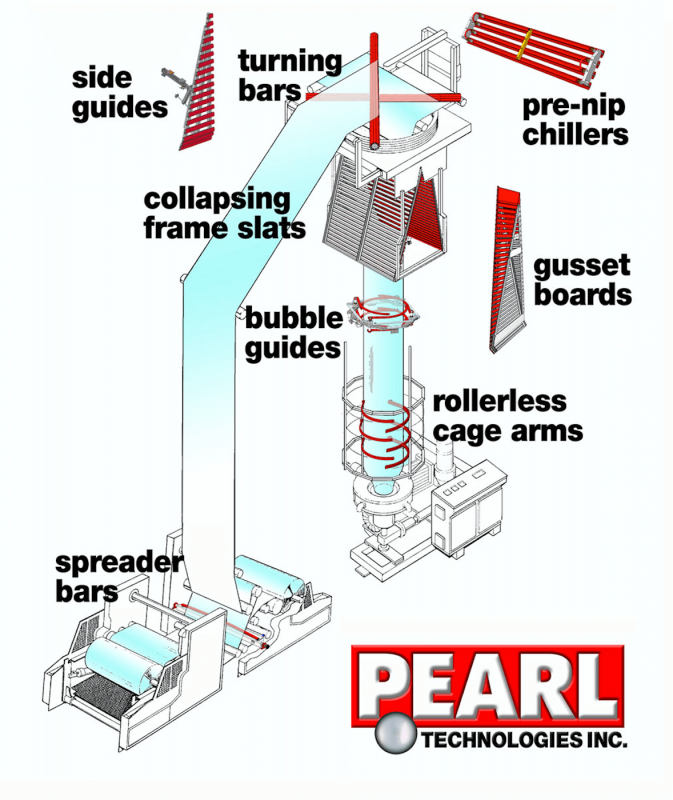

Whether your company is running cast film equipment, or using older, outdated blown film extrusion equipment, it may be time to upgrade with newer equipment from a company such as Pearl Technologies. Doing so can help address the two primary limitations of extrusion, poor film quality and limited output.

By investing in high-quality equipment, extrusion companies can maximize output, reduce maintenance, and significantly increase overall product quality, and this, in turn, results in market growth.

Be Ready for the Future of Extrusion!

As companies like Pearl Technologies continue to innovate in the blown film extrusion space, we expect to see this market grow even more in the future. So, think about what you’ve learned in this article, and consider upgrading your equipment and whether implementing a new blown film extrusion process in your plant is the right choice for you.