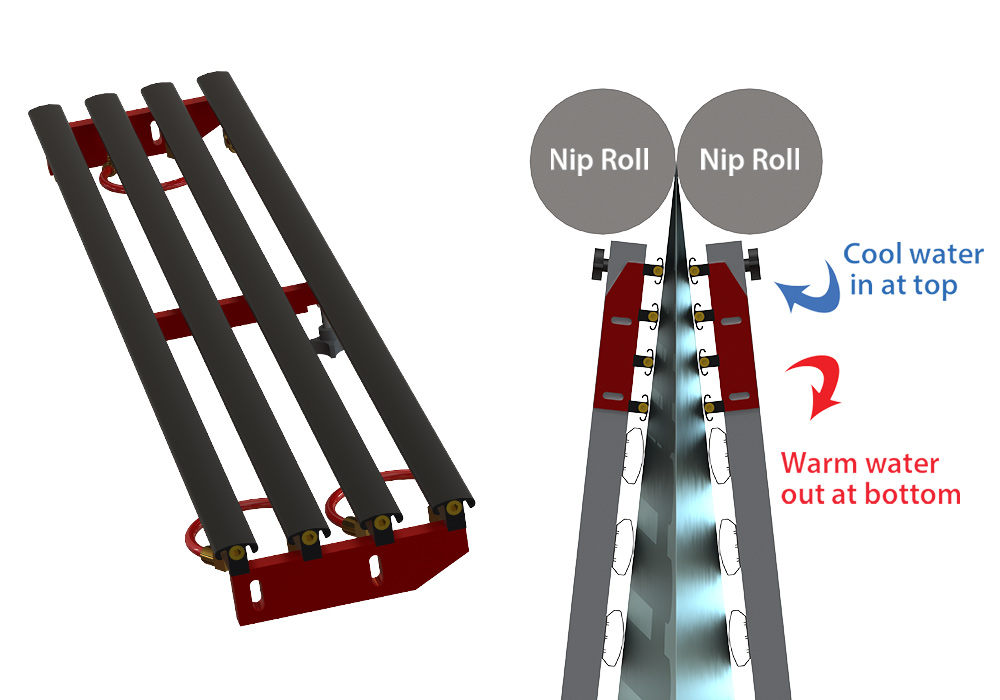

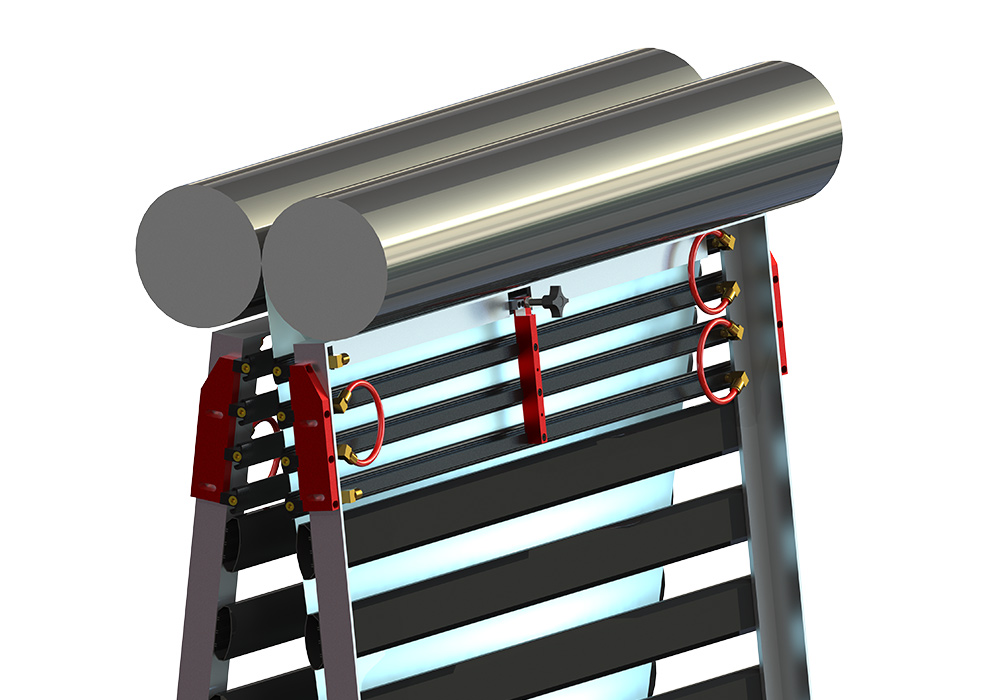

Pre-Nip Chiller

The last critical contact area rarely utilized is just prior to the nips

Pearl understands the importance of lowering the bubble temperature in blown film applications. Count on our Pre-Nip Chillers to maximize output by keeping your film running cooler all year round.

Stop wasting money on expensive additives that affect the quality of your film. Let the technology of Pearl’s Pre-Nip Chillers run your film lines 30-50˚F cooler. This guarantees faster output, lowering your costs. Ready to ship in less than a week.

Please note, Pearl’s Pre-Nip Chillers are designed to work in conjunction with a Temperature Control Unit (TCU). Coolant temperature must be controlled in accordance with the film operating temperature to function properly. Do not attempt to operate off direct plant water unless it is temperature controlled.