We are proud of our ability to supply wicketed bag manufacturers with many critical components along the production line. Our web handling and wicket hub and arms are the best in the business, and our punches and precision punching units meet your need for speed and clean holes and slits.

For additional information, download a copy of our Wicket Solutions Flyer or contact the Sales Team to request product-specific data sheets. Be sure to check out our blog post on our Wicketed Attachments too!

When it comes to innovative, engineered wicket bag solutions, no one does it better than Pearl.

Connect with our Sales Team today:

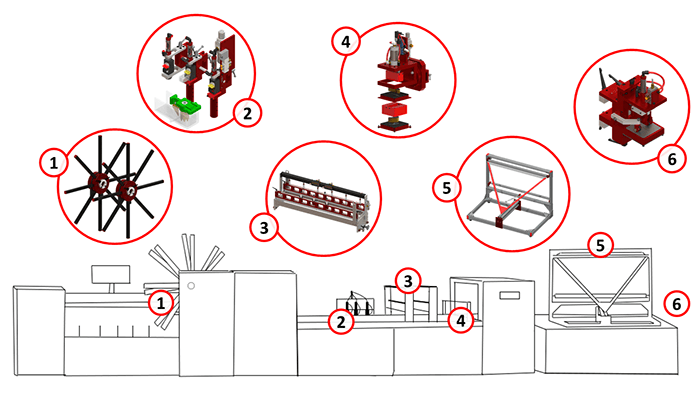

#1 Wicket Hubs & Arms

Pearl’s Wicket Hub and Arms are designed for wicketed bags. The unit can be retrofitted on any OEM wicket bag machine. Available in various arm lengths and configurations.

#4 Flex Units

Interchangeable punch and die systems that produce high quality holes. Decrease downtime with added convenience. Various shapes and sizes available.

#2 Lightning Wicket Attachment and Punches

Safety box changes punches in seconds. Built-in scale for quick hole spacing adjustments. Patented clamp extends punch life. Simple mounting and installation. Quick cylinder removal.

#5 Folding “V” Board Covers

Retrofits available to fit any OEM fold board. Various wear coverings available in either plastic or coated aluminum, each with different material surface properties. These are food packaging friendly!

#3 Multi-Punch Unit (MPU)

The one-piece punch design ensures fast punch change outs, snapping in and out in seconds, to yield more efficient production lines. Great for vent punching. Simple and tool-less.

#6 Rotary Perf Unit

Unique in design, an upper rotary tooth blade plunges down into a die plate while the poly web is being pulled through the unit. Works well with poly webs that require a tear feature.