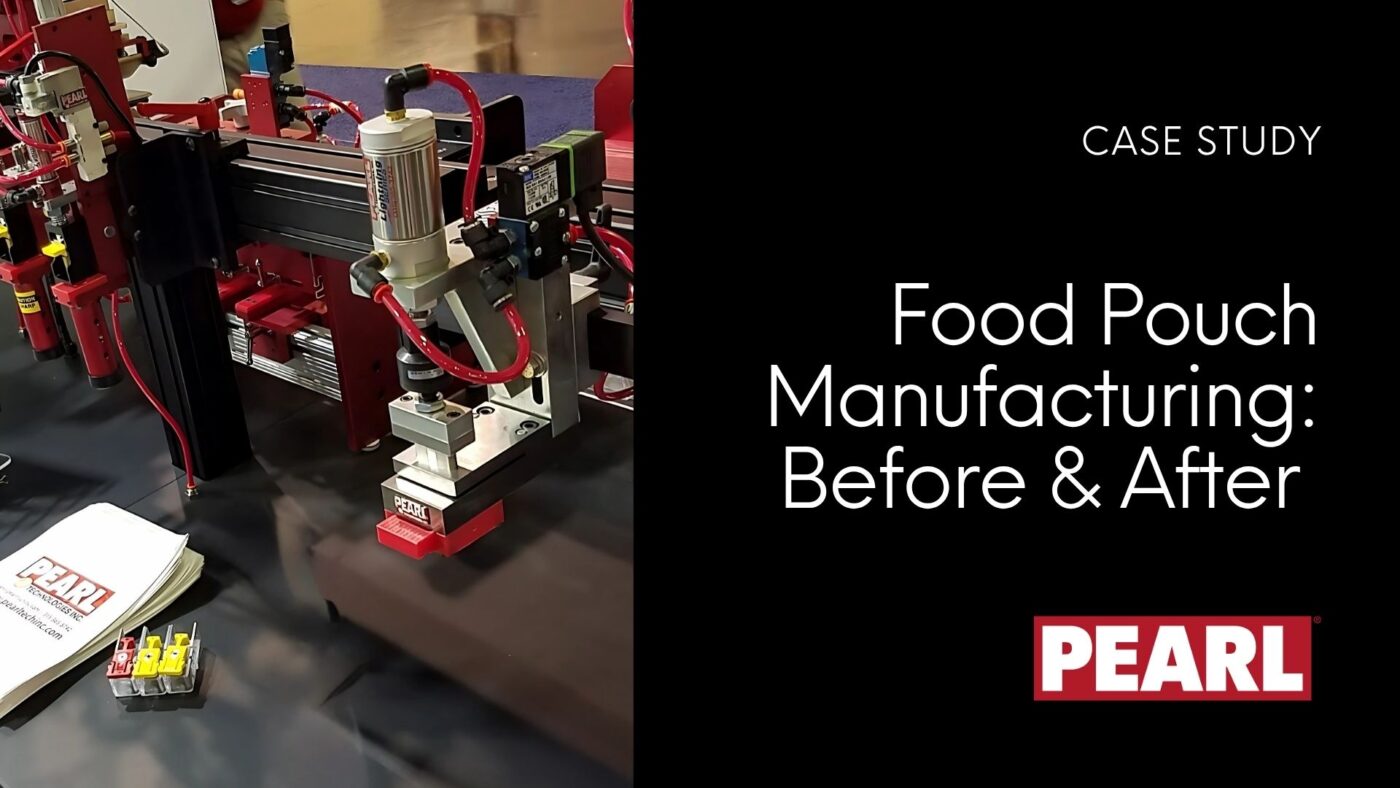

Pearl Technologies, an EDGE Industrial Technologies brand, recently partnered with a leading producer of squeezable fruit pouches to optimize their manufacturing process. The Pearl customer utilizes six lines to convert rolls of flexible film into food-grade pouches, each equipped with eight zero-clearance units responsible for corner cropping. Challenge The existing punch units, manufactured by a […]

Category Archives: Blog

For manufacturers in flexible packaging, efficiency and adaptability are of the utmost importance. Pearl’s Flex Units are designed to meet these demands, offering unparalleled versatility to tackle multiple punching tasks with precision and ease. A Unit That Adapts to Your Needs Our Flex Units are engineered to excel in a variety of industries, from food […]

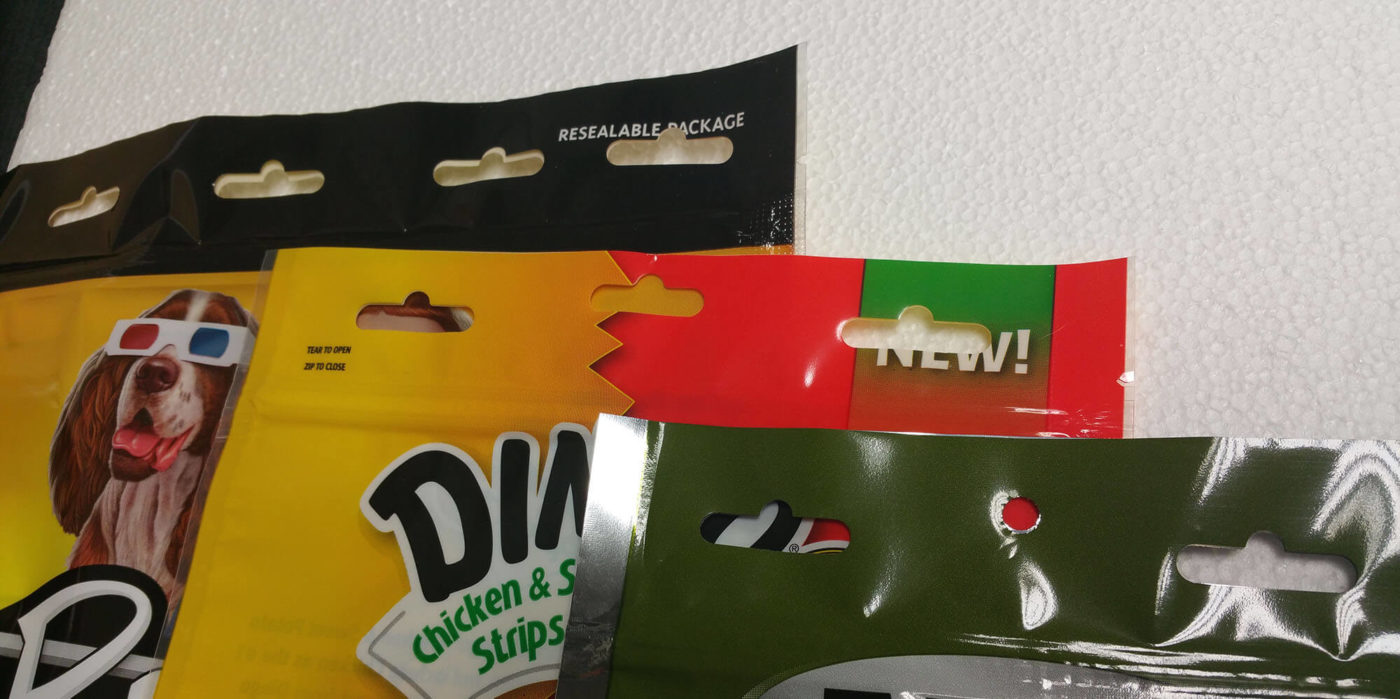

In the fast-paced world of packaging, every detail matters. This includes the tiny hanger holes and tabs that can make a big difference in product presentation and functionality. Whether you’re packaging snack bags, hardware items, or clothing, selecting the appropriate hanger hole punch is crucial for ensuring products stand out on the shelves and optimally […]

Pearl Technologies, a leader in offering the right technology and machinery to answer growing customer demand. There’s been few packaging innovations that have taken the world by storm like pouches have. Go to any zoo or park, and you’ll see plenty of children enjoying their pouch snack. And it’s not just food—the beverage industry has […]

Punches Make a Different in High-Quality and Consistent Packaging Operations Choosing the right punch for your flexible packaging operation is essential to ensuring quality and consistency in your product. Knowing how much you need to spend on punches to get the consistent quality you need is a key part of your business value proposition. Toothed […]

Flexible packaging punches need to deliver crisp, clean cuts on tough material, time after time. Here are some tips to make sure your hole-making punches keep their edge. 6 Steps to Keep Your Industrial Punches Sharp Repetitive clean cutting of the tougher films and laminates puts a lot of pressure on your punch tooling. Whether […]

Tis the season of giving and Pearl Technologies and its employees have once again come together for the holiday season to gather toys for less fortunate kids. Here’s to hoping we’re able to help spread the holiday cheer this year! Toys were donated to Helpful Hearts Community Closet, Inc., a non-profit charitable organization. To learn […]

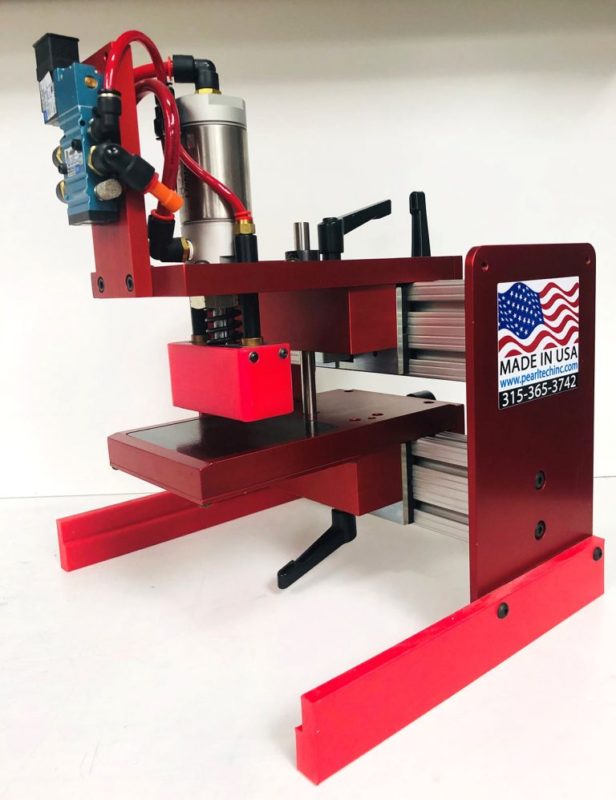

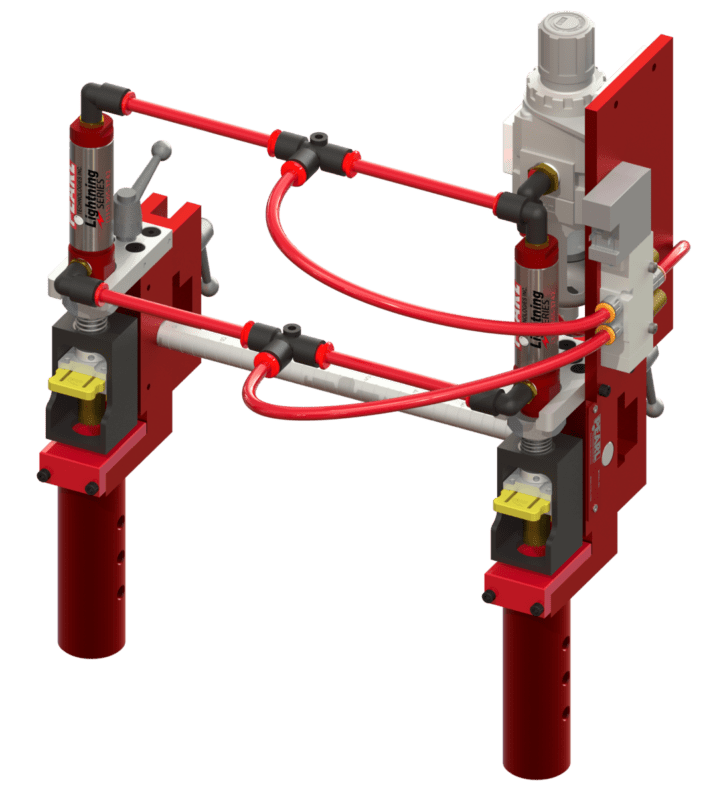

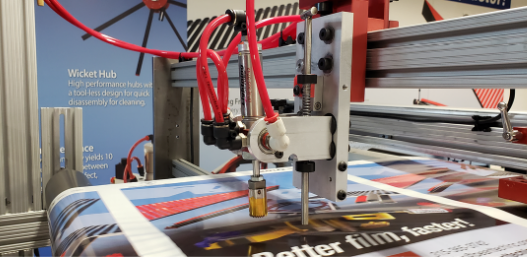

If you’re looking for superior quality punching machinery for flexible packaging, Pearl Technologies’ Zero Clearance and UltraFlex HD units offer an industry-leading combination of customizable options and flexibility while delivering true die cut precision cutting. Let’s take a look at what sets these punch units apart, and which offers the best mix of features and […]

Safety is always a top priority and flexible packaging is no exception. Let’s take a look at some key punching machine safety features that protect your most valuable asset: your people. Great design starts with simple, well-thought-out features that make machines safe and easy to operate. From simple storage solutions that make common accidents less […]

Fast, clean, and consistent cutting of pouch packaging material or blown plastic film is only possible with exactly the right punch and die clearance for your application. While many cut-rate suppliers may save you money upfront, a reputable technology partner will work with you to identify the best combination of punch unit, punch attachment, and […]