Pearl Technologies, an EDGE Industrial Technologies brand, recently partnered with a leading producer of squeezable fruit pouches to optimize their manufacturing process. The Pearl customer utilizes six lines to convert rolls of flexible film into food-grade pouches, each equipped with eight zero-clearance units responsible for corner cropping. Challenge The existing punch units, manufactured by a […]

Author Archives: Jennifer Fowler

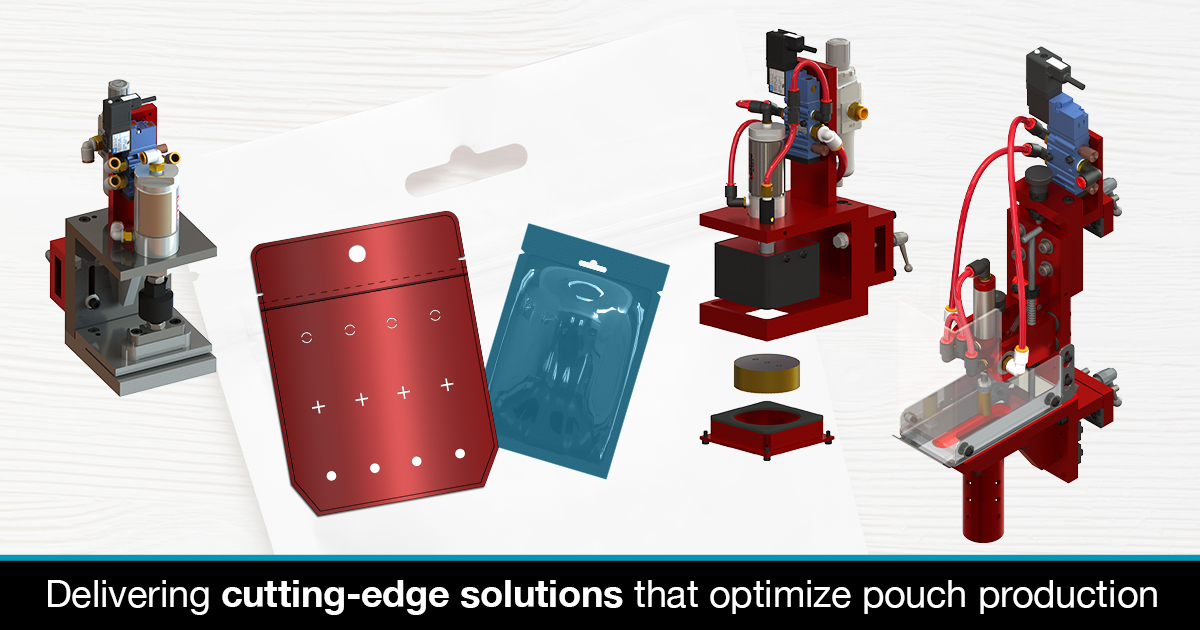

For manufacturers in flexible packaging, efficiency and adaptability are of the utmost importance. Pearl’s Flex Units are designed to meet these demands, offering unparalleled versatility to tackle multiple punching tasks with precision and ease. A Unit That Adapts to Your Needs Our Flex Units are engineered to excel in a variety of industries, from food […]

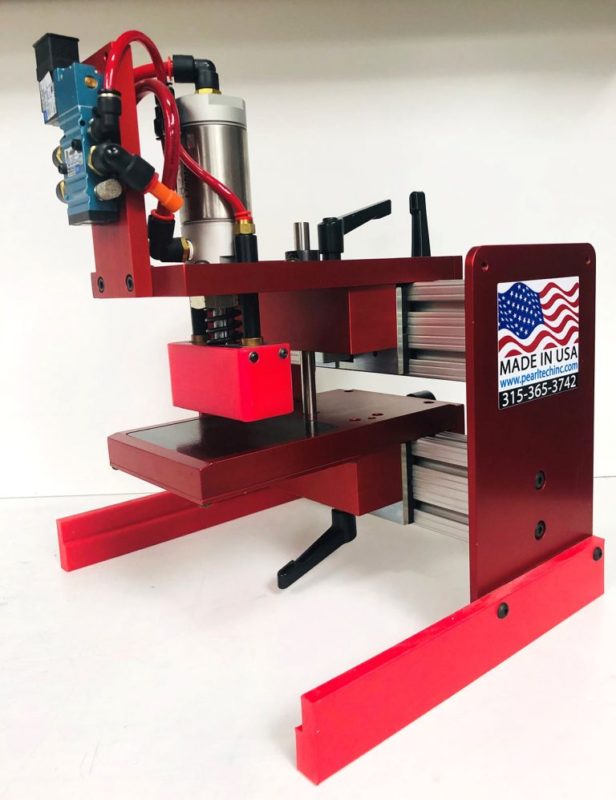

Pearl Technologies, a trusted leader in pouch manufacturing solutions, proudly stands behind its range of innovative products designed to revolutionize production efficiency for pouch manufacturers worldwide. With a steadfast commitment to enhancing productivity and quality, we continue to set the standard in the industry. At the heart of Pearl’s offering are our high-speed punching attachments, engineered […]

Wilder, Kentucky, Dec. 16, 2024 – Matt Webber has been hired as Vice President of Sales at EDGE Industrial Technologies (EDGE), a leading global producer of industrial machine knives and blades, punches, and related equipment. In this role, Webber will oversee global sales activities and teams across all EDGE brands – TGW International, Pearl Technologies […]

Wilder, Kentucky, Nov. 19, 2024 – Lisa Mills has been hired as Key Accounts Manager at EDGE Industrial Technologies (EDGE), a leading global producer of industrial machine knives and blades, punches, and related equipment. Mills will be responsible for building relationships, creating strategies, and identifying the needs of Key Accounts in the food processing & […]

Both units offer capabilities essential for converting and extrusion operations Wilder, Kentucky, Oct. 29, 2024 – Pearl Technologies, a frontrunner in high-speed machine attachments for punching, perforating, and slitting film in the converting industry and brand of EDGE Industrial Technologies has launched two new products – a Value Rotary Perf Unit and a Performance Rotary […]

Wilder, Kentucky, July 8, 2024 – Josh Slagle has been appointed CEO of EDGE Industrial Technologies (EDGE). EDGE is a leading global producer of industrial machine knives and blades, punches, and related equipment. Slagle’s appointment came as part of the recent investment in EDGE by Falfurrias Capital Partners (FCP), a private equity firm focused on […]

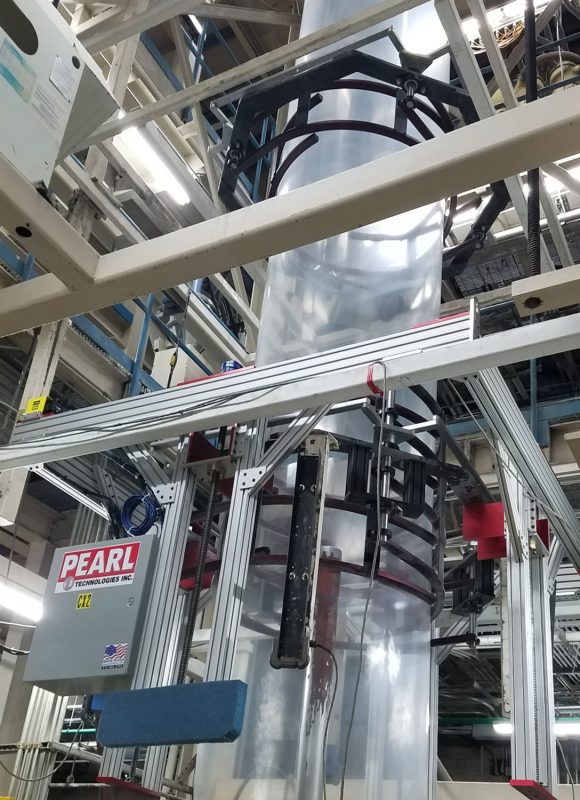

The process of blown film extrusion is a cornerstone technique for producing a wide array of flexible packaging materials. At the heart of this process lies a series of intricate equipment components, each playing a vital role in ensuring the quality and efficiency of the final product. The Extrusion Process for Blown Film Blown film extrusion […]

Ventilation is key in keeping certain goods in optimal condition, especially when it comes to items that need to breathe, retain freshness, or drain moisture. This is where vented bags come into play, offering a simple yet essential solution. Let’s take a look at the nature of vented bags and how they serve various industries […]

Ryan Neil joins as Regional Sales Manager, Ann Kelsey promoted to Channel Strategy Manager Wilder, Kentucky, Jan. 31, 2024 – Pearl Technologies, a leader in creating high-speed machine attachments for punching holes, perforating, and slitting film in the converting industry and brand of EDGE Industrial Technologies, announces two strategic team updates. Ryan Neil was hired […]