If you’re looking for superior quality punching machinery for flexible packaging, Pearl Technologies’ Zero Clearance and UltraFlex HD units offer an industry-leading combination of customizable options and flexibility while delivering true die cut precision cutting.

Let’s take a look at what sets these punch units apart, and which offers the best mix of features and pricing for different flexible packaging applications.

Die Cut Options for Sheer Quality

Die cut punching is the go-to option when there is no room for compromise on hole quality, especially if you are handling thicker films typically used in flexible pouch manufacturing and high-end venting and bag making.

Pearl Technologies’ top-of-the-range Zero Clearance and UltraFlex HD punching machinery offer converters, packaging contractors, and specialist manufacturers a range of choices for delivering unmatched die cut quality when it really counts. Let’s break it down.

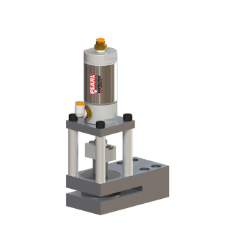

Performance Zero Clearance Punching Machine

Pearl’s Zero Clearance punching units produce the best-quality hole you can cut without using expensive, small-run laser technology.

Designed for intermittent punching, our flagship Performance Zero Clearance model is engineered to the tightest tolerances to deliver a sheer cut hole every time, even on the toughest laminates and metalized films, while our fully customizable precision-made resharpenable die cut punches offer unmatched durability.

Key Features

Built to deliver uncompromising quality for the most demanding applications, our Performance Zero Clearance model offers:

- Superior quality die cut punching

- Resharpenable stainless steel punches are capable of delivering millions of cuts, depending on the material

- Fully customizable punch and die sets made to your exact specifications

Additional Features

Our Performance Zero Tolerance punch unit also features:

- Three sizes (1.25” max. diameter, 3.5” max. diameter, and 1”x3.5” handle hole)

- All-steel construction for maximum unit durability

- Included custom-designed pneumatic valves and mounting clamps

- Low maintenance construction with no lubrication required

Best Applications

While the quality and durability of our finest punching machine is a great investment for any flexible package operation, the Performance Zero Clearance unit’s standout performance on challenging materials and multilayer films, plus its fully customizable tooling, make it ideal for high-quality pouch-making and bagging applications such as:

- Medical pouches

- High-end healthcare, beauty, and food products

- Luxury retail bags and packaging

Value Zero Clearance Punching Machinery

Pearl Technologies’ Value Zero Clearance unit delivers comparable cutting to the industry-leading die cut punching performance of our flagship product in a standardized, budget-friendly package. With quality single-use punches and standardized tooling options, your line will be able to handle bigger pouch or bagging orders while keeping costs under control.

Key Features

Our Value Zero Clearance unit offers high-quality design and medium-tight tolerances to ensure both consistent clean-cut performance and practicality. Look for:

- Excellent single-use, non-sharpenable punch guide and die sets

- A choice of popular standard hole shapes and sizes

- A single-size configuration (1.25” maximum diameter)

Additional Features

Our Value Zero Clearance unit also features:

- A durable aluminum body with steel insert and punch

- Available custom pneumatic valves and clamps

- Low-maintenance construction, with no lubrication required

Best Application

Smart design and standardized configurations put premium performance within your reach. The Value Zero Clearance punch machine is a great choice for ensuring quality on high-speed dedicated bulk operations or for leveling up your line to bring in a special contract. Our Value Zero Clearance machines are always in stock, with lead time dependent on your tooling setup.

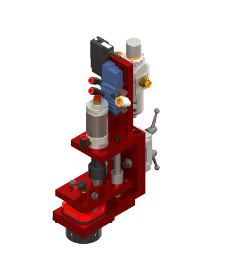

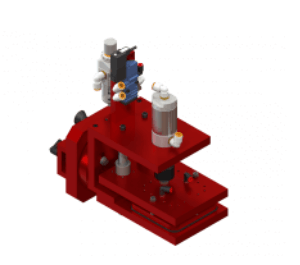

UltraFlex HD Punching Machine

Pearl Technologies’ unique UltraFlex HD intermittent punching assembly combines the unmistakable edge of true die cut technology with the flexibility and ease of use usually associated with conventional toothed-punch equipment. Add in fully customizable tooling for an unbeatable combination of quality and convenience.

Key Features

Stay nimble with a tight-tolerance punching machine that combines premium custom cutting capabilities with the ability to pivot between projects. Our UltraFlex HD model includes:

- Interchangeable die sets that allow you to swap tooling between runs

- Fully customizable punch and die sets made to meet your exact specifications

- Our patented web clamp ensures every cut lands exactly where you want it

Additional Features

The UltraFlex HD also features:

- Two sizes (1.375” maximum diameter, 4.25” maximum diameter)

- Lower cost than traditional zero clearance units

- Low maintenance construction

- Unbeatable flexibility, quality, and affordability for maximum value and ROI

Best Application

The ability to switch between fully customized toolings while still delivering cut-edge quality comparable with traditional zero clearance units makes the UltraFlex HD the ideal choice for smaller multi-SKU operations or contractors looking to handle a wide range of challenging materials in the fast-growing premium flexible pouch market.

Pick Pearl for Punching Perfection

Whether you seek the unmatched edge quality of our Zero Clearance units or the unbeatable versatility of our UltraFlex HD unit, Pearl Technologies has precision-crafted punching machinery that will serve your needs today and equip your business for tomorrow.

Whatever you choose, you’ll have a choice of metric and imperial tooling, while all our units are compatible with our vacuum tube slug removal technology to keep your line clean. For the best possible results, allow us to pre-test your film material in our Application Lab. We will determine the most efficient and cost-effective way to deliver more hole-punching bang for your buck.

Click below to learn more about how Pearl Technologies’ precision punching machinery can best serve your needs.