Fast, clean, and consistent cutting of pouch packaging material or blown plastic film is only possible with exactly the right punch and die clearance for your application.

While many cut-rate suppliers may save you money upfront, a reputable technology partner will work with you to identify the best combination of punch unit, punch attachment, and punch-die clearance for your material to ensure you get the results you were expecting.

Mind the Gap: Packaging Punch and Die Clearance

The consistency and speed of your hole punching process are only as good as the combination of punch and die clearance, line motion, and attachment design your process employs.

While many U.S. and overseas-based market players provide off-the-shelf equipment that might seem to meet your needs, you could soon find yourself having to replace a unit that fails to perform how you were expecting at the speeds you require. It pays to work with a trusted partner who can deliver on all parts of the plastic punching equation at once.

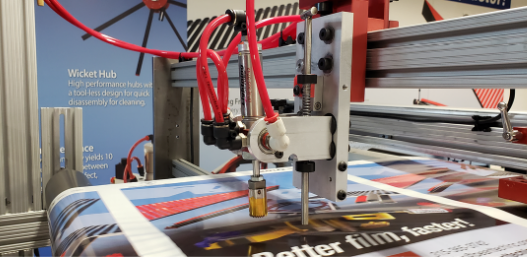

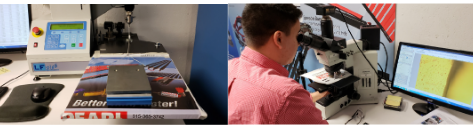

To meet this need, Pearl Technologies has developed its own in-house application lab to develop optimized hole-punching solutions for our customers. Here’s how it works.

Value-Added Punching Solutions

Pearl Technologies’ Application Lab can identify the best equipment for your application using original samples of your materials. To do this, we look at three key variables in the production process.

Punch and Die Clearance

Punch and die clearance is the key variable in ensuring the cleanest cuts for your material. The tighter the tolerance between your punch adaptor and the die supporting your material, the less tearing and deformation will occur during cutting, resulting in a cleaner hole.

At the same time, the thicker your material, the more clearance may be required to effectively separate it.

Punch Attachment Design

The combination of punch and die clearance and materials in your application will also affect your choice of punch attachments.

For example, Pearl’s patented die cut punch attachments work with our premium quality Zero Tolerance and versatile Ultraflex HD punch units to offer superior cutting of the heaviest composites and laminates.

Line Motion

Our Application Lab is also capable of simulating your line speed, including both intermittent and continuous motion operations.

Pearl works with you to determine the best equipment configuration to achieve both consistent high-quality cutting and the holes per minute your operation requires, based on your budget.

Reducing Risk, Optimizing Performance

There is no substitute for Pearl’s 30 years of experience in matching punch equipment to your materials and process. Our Application Lab allows us to bring our knowledge and expertise to bear to optimize your performance and identify potential savings, all while giving you the peace of mind that you will be able to achieve the same results in your facility.

For example, technical analysis of your production materials in the Application Lab can help us determine the ideal punch to die clearances to deliver:

- The cleanest possible holes in high-end pouch materials

- High-volume handle punching for bag making

- Superior performance from our lower-cost value toothed punch adaptors

Pearl’s Four-Step Application Lab Process

When you contact Pearl’s Application Lab for hands-on assistance with your production process, we ask a lot of questions about your business before going to work on a solution that works just for you. Here’s how we do it:

Step 1: Preliminary Questionnaire

We’ll send you a questionnaire that asks questions about the type of products you make, the materials you use, the line speeds you operate under, and specific production challenges you already face.

Step 2: Follow-up Questionnaire

We’ll analyze your answers to deliver a focused follow-up questionnaire with detailed information about how your needs might best be served by specific units in our punch model range, including our high-tolerance Zero Clearance machines and Ultraflex HD machines, our standard tolerance Flex and Lightning lines and our high-speed ball and die and pivot machines.

Step 3: Test and Analyze

We will test your material, running specific tests in the Application Lab using samples you supply to provide both a detailed technical report and specific product recommendations to help guide your buying decision-making process,

Step 4: Recommend Solution

We work with you to select, customize, and configure the specific units you prefer for your operation. We’ll also help you troubleshoot any post-installation problems that might emerge as you bed down your new equipment.

Pearl: Your Trusted Punch Technology Partner

At Pearl, we are focused on making your application better with high-quality products and custom-designed solutions. Our Application Lab is a key part of that and is fully equipped to handle a wide range of product testing, including:

- Side-by-side analysis of different pouch attachments

- Pretesting of customer-supplied film or sample

- Trials for intermittent vs. continuous application

- Coefficient of friction testing

We’ll work with you to put together the best combination of punch and die technology and high-quality punch attachment to suit your product materials and line speed. We are committed to providing equipment that delivers the consistency and quality you expect while saving you time and money over the long term.

Click below to learn more about our wide range of standard and customizable punch attachments.