Safety is always a top priority and flexible packaging is no exception. Let’s take a look at some key punching machine safety features that protect your most valuable asset: your people.

Great design starts with simple, well-thought-out features that make machines safe and easy to operate. From simple storage solutions that make common accidents less likely to happen to clear, consistent warning labels, the best punching machines come with built-in systems to keep your team safe, confident, and on task all day every day.

10 Punching Machine Safety Features

Let’s take a look at some key safety features that top-quality punching machines can bring to your flexible packaging line:

1. Cut Prevention

Cuts are the primary hazard for staff operating and maintaining punching machinery. Punches need sharp edges to perforate plastic film and laminates and need to be switched regularly. Well-designed equipment makes it easy to handle sharp punches with minimal risk.

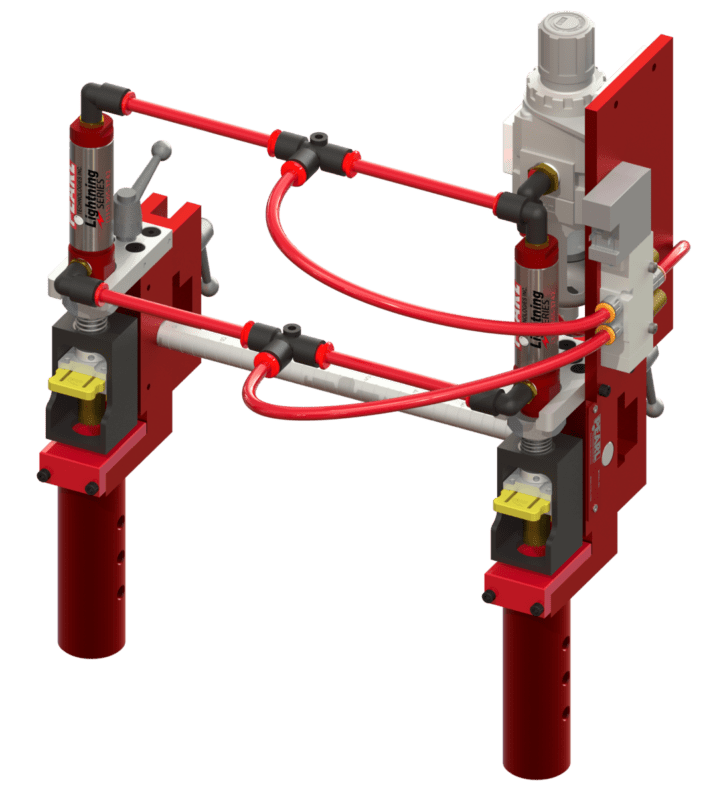

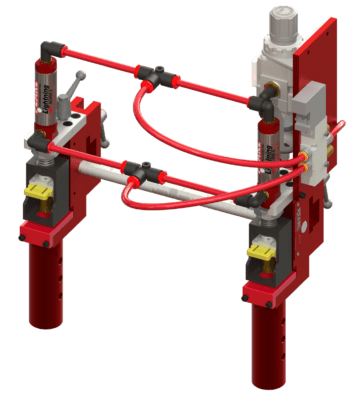

Pearl Technologies’ industry-leading Safety Box system eliminates exposure to sharp edges during tooling changes for their versatile Lightning Unit. Our specially designed plastic holders mean workers never come in contact with punch edges.

We also provide plexiglass peripheral guards for our rotary pin units and other perforation equipment where there is a potential for operators to come in contact with moving blades. Our stock rotary blades ship with a plastic cover to prevent injury while installing, and you can even ship us your used blades for recycling.

2. Safe Storage

It sounds obvious, but simply ensuring toothed punches are properly stored when not in use can go a long way to improving safety.

Pearl can provide dedicated storage for your punches that will also prevent teeth from being blunted or bent by accidental contact with surfaces.

3. Tight Clearances

Well-designed equipment improves both cutting quality and safety with close tolerances and tight clearances.

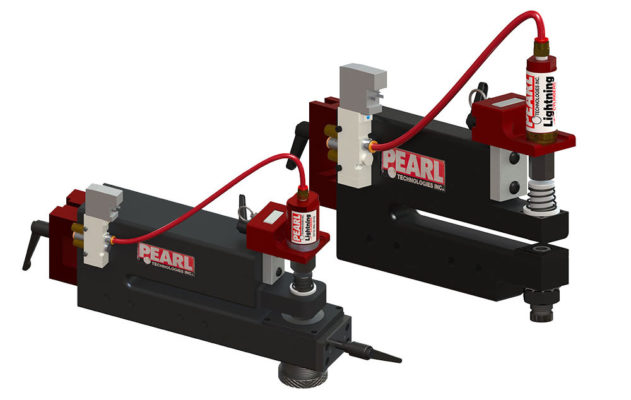

While operators should never touch working machinery, Pearl’s die cut punch units and our specially designed web clamps for use with our teethed equipment improve cutting performance and keep fingers away from cutting edges.

4. Toolless Changeout

Making punch changes and adjustments toolless both improves safety and reduces the chances of machine damage.

Pearl’s Lightning Unit and other equipment allow toolless punch changes in seconds, making line reconfigurations quick and painless.

5. Easy Access

Making it easy to access tooling and guides that need to be changed out or adjusted also helps to prevent accidents. This is especially important on heavier equipment or larger machines.

To ensure safety while changing out the 12-inch blade on our large Flex 5 Unit, Pearl developed an innovative clamshell design that allows the punch to be accessed from above, rather than requiring operators to reach in under the machine.

A smart design is a safe design.

6. Noise Reduction

Some punching machines can be noisy, particularly ball and die or pivot punches operating on continuous lines.

Quality equipment includes features to mitigate noise, even if the punch isn’t the loudest machine in the room. Pearl designs its equipment with muffling and dampening equipment and can provide soundproof boxes for units where noise is a particular concern.

7. Heat Guards

Hard-working equipment can get hot, including the pneumatic equipment used in air-driven punches.

Pearl adds heat guards to air cylinders or other equipment that could pose a risk and clearly labels surfaces that are hot to the touch.

8. Safety Integration

Our equipment is only as safe as the line it operates on.

Pearl works with clients to build-in safeguards such as kill switches to quickly cut power to our units or the entire line if anything goes wrong. We can also provide sensors that prevent equipment from operating if access panels or safety guards are not properly replaced.

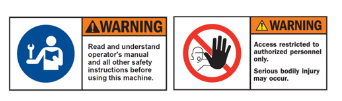

9. Warning Labels

Safety starts with awareness, so fully featured equipment should always include clear, standardized warning labels and markings. Pearl works with industrial design experts to ensure visual warnings on all our equipment meets or exceeds industry requirements.

10. Training

Top manufacturers stand behind their equipment. At Pearl, that commitment includes safety systems. We can provide safety training whenever required, including on the use of our no-touch Safety Box system for our Lightning units.

Safety Is Part of the Solution

At Pearl Technologies we deliver optimized, often customized solutions that meet the needs of your particular application and we stand behind the products we make. Our team continues to innovate safety equipment to meet the needs of individual customers that we then incorporate into our full range of equipment and service offerings.

Talk to us about how we can help you punch better at higher rates while still protecting the people who help make your product great.

Click below to learn more about our fully featured range of punching units.