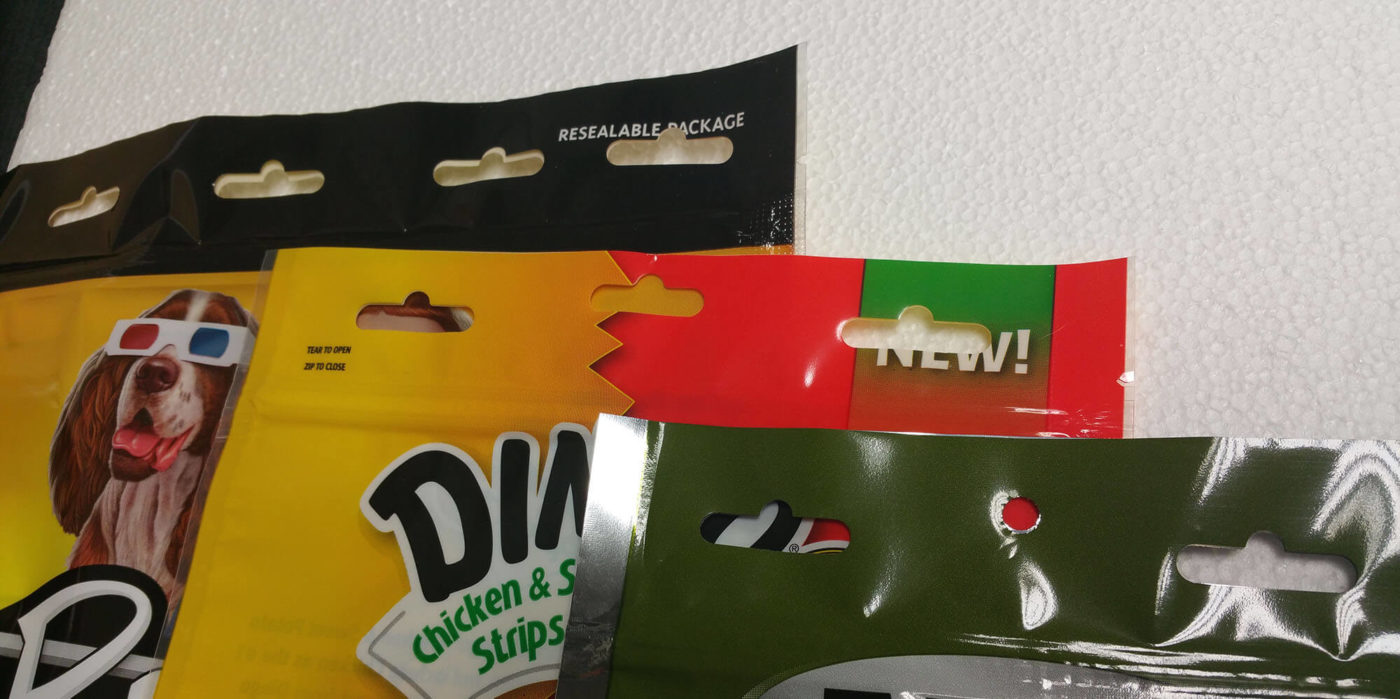

In the fast-paced world of packaging, every detail matters. This includes the tiny hanger holes and tabs that can make a big difference in product presentation and functionality. Whether you’re packaging snack bags, hardware items, or clothing, selecting the appropriate hanger hole punch is crucial for ensuring products stand out on the shelves and optimally perform throughout their lifecycle.

In this guide, we’ll delve into the various types of hanger holes and tabs, explore the punches used to create them, and provide insights into choosing the right punch for your packaging needs.

Understanding Hanger Holes and Tabs

Hanger holes and tabs serve a dual purpose in packaging: they facilitate easy display of products and enhance brand visibility. Different products and packaging designs require different types of hanger holes and tabs to achieve the desired presentation and functionality. Common types include round hanger holes, euroslots, inverted-T holes, and osha holes–each offering unique benefits in terms of stability, visibility, and ease of use.

Round Hanger Holes

Uses and Benefits: Round hanger holes are versatile and widely used for a variety of products, including food packaging, hardware items, and clothing. They are suitable for hanging products on hooks or pegs in retail displays and offer excellent stability and support for various product weights. They are easy to implement and provide a clean, unobtrusive look on packaging.

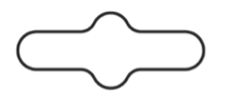

Euroslots

Uses and Benefits: Euroslots are commonly found in retail packaging for items such as electronics, toys, and household goods. They are designed to hang securely on Euro hooks commonly used in European retail environments. They also offer a sleek and professional appearance on packaging.

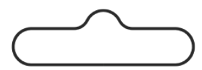

Inverted-T Holes

Uses and Benefits: Inverted-T holes (also referred to as sombrero holes) are commonly used for packaging items such as bags of snacks, pet treats, and hardware components. They are designed to accommodate various types of hanging fixtures, including peg hooks and display racks.

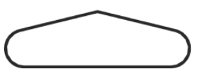

Osha Holes

Uses and Benefits: Osha holes (also referred to as delta holes) are shaped like a triangle with rounded corners and are often used for hanging heavier items such as power tools, automotive accessories, and household appliances. They are designed to distribute weight evenly and provide maximum stability while providing a distinctive look on packaging to help products stand out on retail shelves.

Types of Punches for Hanger Holes and Tabs

Choosing the right punch for creating hanger holes and tabs is essential for achieving consistent results and maximizing production efficiency. Several types of punches are available, including manual, pneumatic, and servo-driven. Each type offers distinct advantages in terms of speed, precision, and ease of operation.

- Manual punches are suitable for low-volume production or prototyping purposes, providing flexibility and control over the punching process.

- Pneumatic punches are ideal for medium- to high-volume production, offering fast and efficient operation with minimal operator fatigue.

- Servo-driven punches represent the cutting edge of punching technology, delivering precise control over punch speed, force, and positioning for unparalleled accuracy and consistency.

Selecting the Right Teeth for Your Industrial Punches

The teeth configuration of a punch plays a crucial role in determining the quality of the punched hole or tab. Common Pearl designs include piranha, barracuda, shark, and tru-kote teeth, all found in our VIP Punch Family. Each offer specific benefits in terms of clean cutting, reduced wear, and extended punch life.

- Barracuda teeth are suitable for general-purpose punching applications, providing a balance of cutting efficiency and durability.

- Piranha teeth are ideal for precision punching tasks that require smooth edges and minimal material distortion.

- Shark and Tru-Kote teeth, sometimes coated with titanium nitride (TiN) or titanium carbonitride (TiCN), offer enhanced wear resistance and prolonged tool life, making them ideal for high-volume production environments.

Choosing the Right Punch Material

The material composition of a punch significantly influences its performance and longevity on the production line. Common materials include tool steel, high-speed steel (HSS), and carbide. Each material offers unique properties in terms of hardness, toughness, and resistance to wear and abrasion.

- Tool steel punches are cost-effective and suitable for moderate to high-volume production, offering good wear resistance.

- HSS punches provide increased hardness and heat resistance, making them ideal for high-speed punching applications where temperature and friction are significant factors.

- Carbide punches offer the ultimate in hardness and wear resistance, making them ideal for cutting abrasive or hard materials and maximizing tool life in demanding production environments.

Connecting Solutions with Pearl Technologies

At Pearl Technologies, we understand the critical role hanger holes and tabs play in packaging efficiency and product presentation. Our comprehensive range of punching solutions are designed to meet the diverse needs of the packaging industry while delivering unparalleled performance, reliability, and precision.

Our expert team works closely with customers to identify their specific requirements, test film in our application lab, and recommend the best punching solutions for their unique applications. Whether you’re looking to enhance brand visibility, improve production efficiency, or reduce equipment downtime, Pearl Technologies has the expertise and resources to help you achieve your goals.