At Pearl Technologies, we’re proud to provide our customers with all of the components they need to add modifications to wicketed bags, such as vents, holes, or perforations. If you’re a wicketed bag making manufacturer, we have everything you need – from wicket hubs and arms to precision punching units to web handling equipment and more.

Not sure what a wicketed bag in? In this blog, we’ll explore the basics and benefits of wicketed bags. Get all the details you need now.

What Are Wicketed Bags & How Are They Used?

Wicketed bags are usually made of PE, LDPE, or PP, and are stacked and held on wicket pins. This type of bag has a lot of versatility. They can be printed or coated depending on the application, and can be manufactured with a bottom gusset, full vents or butterfly vents, perforations, and more – as well as permanent or resealable tape to close the bag. Wicketed bags are commonly used in a variety of industries:

- Bread and bakery bags

- Diaper bags

- Hygiene bags

- Ice bags

- Retail or shopping bags

The Benefits of Working with Pearl

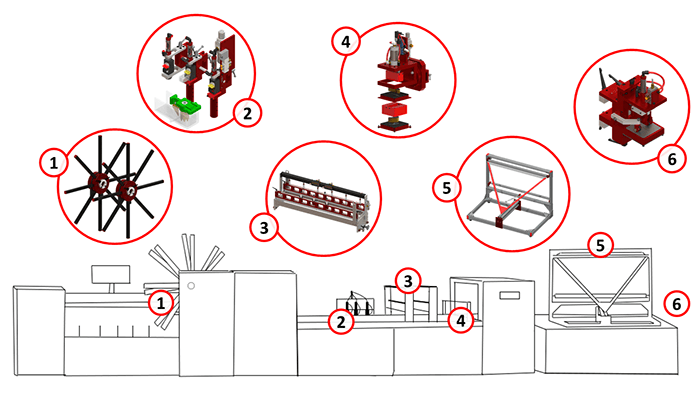

We are proud of our ability to supply wicketed bag manufacturers with many of the critical components along the production line.

- Our web handling and wicket hub and arms are the best in the business, and can be retrofitted on any OEM wicket bag machine. Available in various arm lengths and configurations.

- When it comes to wicket punches, no one comes close to Pearl quality. Our units are designed to make operation simple and easy. Our one-piece punches snap in quickly, requiring no loosening of screws to adjust the slit-gap ratio. Not to mention, our patented web clamp extends the punch life.

- Need vent holes? Our MPU (Multi-Punch Unit) also utilizes our one-piece design punches to ensure the fastest punch changeouts, yielding you more efficient production lines.

- When your wicketed bags require additional holes, our Flex Units are a great all-in-one solution. Our Flex Units are flexible in design, allowing you to swap out the interchangeable punch and die system’s shapes and sizes, as needed.

- For your web handling needs, we sell our folding “v” board covers. These simply retrofit to your current OEM fold boards. These retrofits are a better solution than Teflon® tape!

- At the end of the line, we offer our uniquely designed center rotary perf unit. The upper rotary tooth blade plunges down into a die plate while the poly web is being pulled through the unit. It works well with poly webs that require a tear feature.

Need Tooling & Products To Make Wicketed Bags? Contact Pearl Technologies Today

At Pearl, we specialize in empowering our customers in the manufacturing industry with the tools and products they need to create better packaging for baked goods and so much more.

Whether you need to replace outdated components, or you’re thinking about adding vents, holes, or perfs to your wicketed bags, we’re here for you. Contact us now or give us a call at 315-365-3742 to get started now.