If you are investing in a plastic packaging operation or expanding an existing operation, you’ll need to look at punching machinery, but how much does a new punching machine cost?

Making the Cut: Estimating Punching Machines Costs

Depending on your flexible packaging processing or converting application, your punching machine is either the final touch to your product or the beating heart of your operation, and that is going to be reflected in the cost of upgrading or expanding your operation.

Whether you need a powerful fully-tooled punch to add multiple hang tags and tear notches to composite film pouches or you just want to be sure your plastic bags have handles, clean, accurate punching plays an outsized role in determining the quality of your final product — so it’s worth getting it right.

Let’s take a look at some of the factors that go into determining punching machine cost, including areas where spending a little bit more now will mean saving later.

Punching Numbers

A punching machine is an important piece of equipment with just one job, but a number of factors go into making sure it works effectively with the rest of your operation. These include:

Size and Speed

What is the capacity of your process and what speed do you want to run it at? What punch do you need to cut the size hole you require? Are you processing a few hundred bags an hour, or punching 2000 pinholes a minute or faster? A punch needs to match the speed of your line, not the other way round, but larger, faster punches will always cost more.

Pearl Technologies works closely with our customers to ensure your investment in punch technology matches your process. We can even test run your product on our equipment at the required speed and capacity using our Application Lab service.

Intermittent vs. Continuous Operation

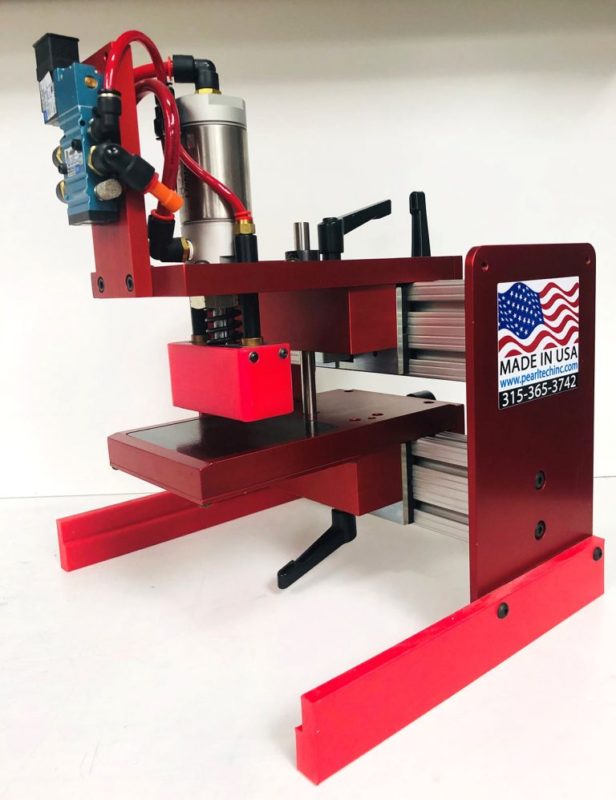

Whether your line runs intermittently vs. continuously will be a big determinant of the type of punching equipment you install. A leading manufacturer like Pearl Technologies can supply distinct products for both, such as its Pivot Punch unit and popular Ball and Die solution for continuous motion lines, and its Flex and Lightning Units for intermittent punching.

Application

What are you punching? While some punches can theoretically handle a range of materials, the smart money says it’s worth working with your supplier to match a machine to your needs.

Whether you are slicing high volumes of a single layer of film or punching holes in high-end foil composite-layer pouches will determine whether you can use a cost-effective standardized toothed punch or a long-lasting customized die cut edge. It will also affect the power and capacity of machinery you should consider.

Shapes

The number, size, and shapes of the holes you are punching are probably the biggest single factor determining punching machine cost. It will determine:

- Whether you can choose a single or multi-punch unit, and

- The size and complexity of the tooling you will run on your units.

For example, Pearl Technologies’ Lightning and continuous motion multi-punch units allow a range of holes to be punched continuously, while our premium Zero Clearance die cut punch unit offers the capacity to cut highly customized shapes into the toughest composites.

Customization

Given the number of parameters a punch solution must meet, off-the-shelf solutions are seldom good investments, even for relatively small operations. Some level of customization is required in most cases, and, while it adds to the cost, a reputable manufacturer like Pearl will ensure your money is well spent and will back up customized products with dependable service.

Premium Equipment

Similarly, investing in higher quality equipment will increase costs but save money in the long run.

For example, Pearl’s resharpenable double-beveled stainless steel punches cost 2-3 times the price of our standard toothed punches, but they can be fabricated into custom shapes and can last three times longer depending on application and use.

Pearl also offers patented web claims and purpose-built hydraulic fittings that can ease integration, lower maintenance and downtime costs, and reduce waste.

The Bottom Line

Punch units can cost anywhere from a few hundred dollars to almost a hundred thousand, depending on your application, making specific pricing estimates difficult. Customization of parts is common and can add 10-20% to costs, and should be considered in your ean somewhat higher prices, but is initial budgeting.

A Punch is a Partnership

At Pearl Technologies we see ourselves as your partner in production. Along with making the highest quality equipment and the longest-lasting punches in the industry, we pride ourselves on providing:

- Customizable punches that will fit your design

- Quality products made in the USA

- A wide variety of standard parts in stock, and

- Our unique Application Lab will test your application on our equipment.

We also offer long-term engineering support for all our equipment that sets us apart in the industry and fast and dependable customer and after-sale support.

If you are in the market for a punching machine for your flexible packaging application, trust Pearl to help you find a solution that matches your process, your product, and your pocket.

Click below to learn more.

[PEARL PUNCHING UNITS >]