Cheap punching machinery might get your flexible packaging product out the door but poor quality punching can cost you more in the long run.

Poor Quality Punching Machinery Can Hit You Where It Hurts

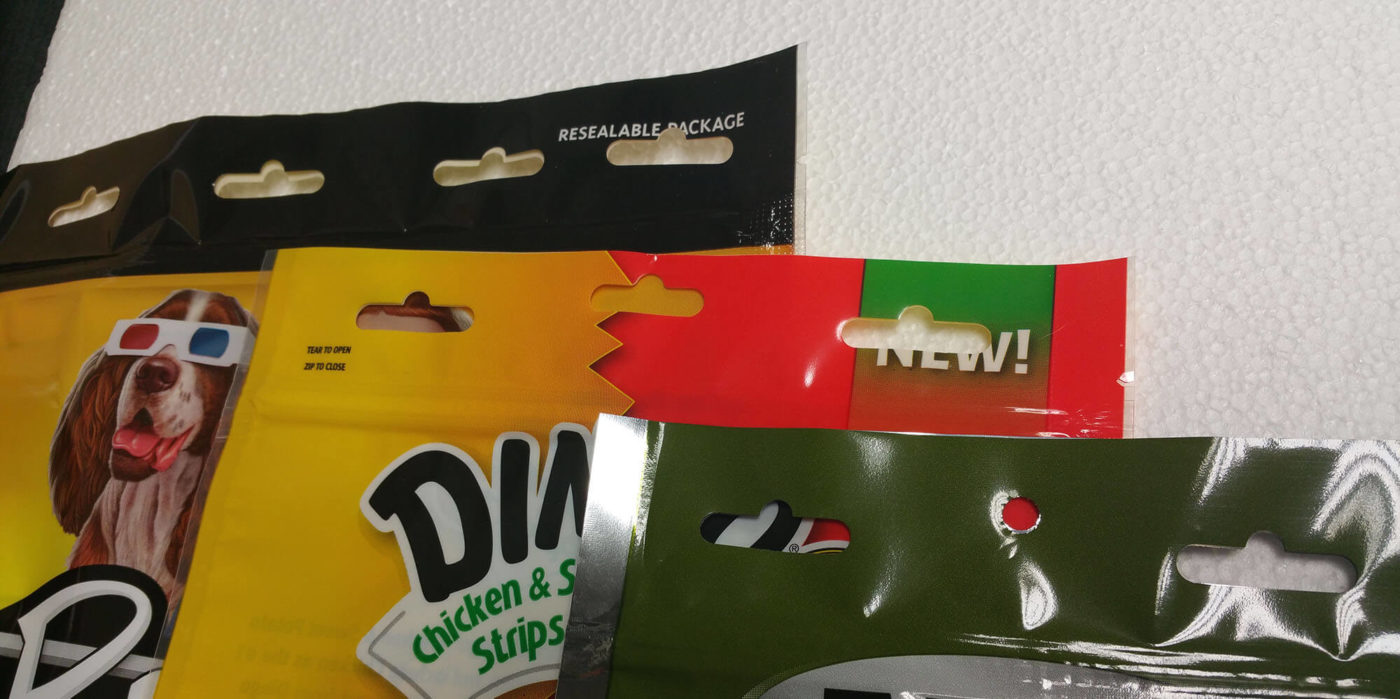

Nothing takes away from the quality of your flexible packaging like shoddy hole punching and placement. Failing to invest in quality punching machinery not only makes your product look bad— it can also cost you plenty in lost time and wasted investment.

Let’s take a look at some of the ways choosing poor-quality punching machinery can impact your operation and what the consequences can be.

Common Punching Problems

New equipment always looks great out of the box, but there are a number of ways inferior machinery can affect your production processes from the get-go:

Wrong Application

Poor advice upfront can mean buying the wrong equipment for your application. Work with a reputable supplier like Pearl Technologies to ensure your punching equipment is designed for the type and grade of material you are processing.

Improper Tool Design

Using the wrong type of die cut or toothed punch on your machine can quickly lead to suboptimal results and reconfiguring adaptors or guides or reordering customized products from third-party suppliers is expensive and time-consuming. Pearl Technologies can match or customize the right punch tools for your application and equipment.

Inaccurate Alignment

Why spend big on great-looking flexible packaging if misaligned punching machinery is going to put a hole where it doesn’t belong. Consistency counts when your reputation is on the line. Pearl Technologies’ high tolerance machines will keep you on track, while many of our toothed punch units feature built-in alignment systems so you get consistent cuts where you want them.

Poor Slug Removal

Hanging, partially detached and loose slugs are more than just an annoyance to your customers — they are a major quality and safety concern. In food packaging, stray slugs can lead to an entire order being rejected and returned, while any plastic debris can damage precision equipment on your line. Our vacuum slug removal technology can stamp out slug problems.

Hard to Find Parts

Low-cost suppliers might not be able to supply replacement consumables or spares. That could see you scrambling to find third-party parts while customers wait. Pearl is an original equipment manufacturer for all its units and supplies both punching units and consumables like punches and blades. We have the part you need.

Real Consequences

No matter the scale and speed of your operation, investing in inferior punching equipment comes with real risks to your product integrity, reputation, and return on investment. Here’s how that looks down the line.

Poor Quality Holes

It might seem like a detail, but ragged holes and ripped plastic not only make your packaging look bad, they can compromise the integrity of your whole product. Choose high-quality double-beveled toothed punches or die cut sheer punches that will cut cleaner for longer.

Increased Maintenance

Keeping lower-quality equipment operating optimally means increased maintenance. Machinery that might not be designed for the demands of your application is going to require routine checks and servicing by qualified personnel. That’s an additional cost that builds up over the lifetime of your machinery.

Machine Downtime

Stopping your line to nurse a finicky punch unit or effect a time-consuming punch switch will cost you every time. Our Flex Units are designed to run longer and to allow punches to be changed quickly and safely. Nearly all of our units are designed for the fastest turnovers so you can swap out worn parts and get your line back up and running in no time.

More Frequent Punch Changes

Poor quality punches will wear out faster and need to be changed or realigned more often. That’s more downtime and more tools and hands where you don’t need them. Our stainless steel and titanium nitride-coated performance punches last longer, and our Lightning Units and punch Safety Boxes make punch changeouts safe, easy, and quick.

Less production

Lower quality machinery is less able to handle the rigors of continuous operation or to scale up to meet additional demand. Increased maintenance, stoppages, and unscheduled downtime will also eat into your production capacity. That can mean disappointed customers, reduced revenue, and a lower return on investment.

Penny Wise, Pound Foolish

The costs of using low-quality machinery can continue to accumulate, eating into any upfront savings you might have enjoyed. Here are some things to look out for when considering the full cost of a punching equipment investment.

Avoid Poor Service and Integration

If your equipment costs less it might be because your supplier is investing less in after-sales service. Don’t be left hanging when things don’t go to plan. At Pearl, we start by designing and delivering the right punching machinery for your flexible packaging needs and follow up with industry-leading after-sales support.

Avoid Expensive Add-Ons

What is included in the price of your punching machinery? You might save money on a punch unit but have to spend more on third-party mounts or pneumatic tie-ins. At Pearl, we supply the right equipment for our machines and some of our units include pneumatic valves and mounting clamps in the price.

Avoid Lack of Customization

Low-cost equipment always means fewer options. That could limit you to just a few choices of punch size or design. Pearl offers a wide range of standard sizes and shapes, and our engineering team is happy to work with you to design customized parts for your applications.

Choose Quality: Pick Pearl

Pearl Technologies makes high-quality punching machinery for flexible packaging processors. Our precisely engineered toothed and die cut punch machinery:

- Cuts more cleanly

- Last longer

- Is more customizable, and

- Is easier, quicker, and safer to change out.

Pearl is an original equipment manufacturer for all of its products. Everything we supply is made right here in the USA. That means:

- We know our own equipment

- We will have your part, and

- We are here to support our products.

It also means we are an end-to-end supplier of both units and consumables. We can help you equip your line and get it running, and when punches or blades wear out, we can replace them with parts that are guaranteed to work.

Unlike lower-priced suppliers, Pearl also helps our customers lower the risk of investing in new equipment. Unique in the industry, our Application Lab allows customers to test their product on our machines before purchase, and design the best possible, fully integrated solution.

Send us your product and we will test it on our equipment at the capacity and line speeds you require. We will work with you to optimize an integrated solution to your needs!

Click below to learn more about our clean-cutting, durable punching equipment.