In blown film extrusion, producing a high-quality, uniform product is the ultimate goal. However, operators often face a frustrating issue known as “blocking.” This common problem occurs when adjacent layers of plastic film stick together, making them difficult to separate. Blocking not only compromises the final product’s quality but also hurts production efficiency and can […]

Category Archives: Blog

In plastics manufacturing, efficiency and product quality are paramount. Every component on your production line plays a crucial role, and web handling is no exception. Wrinkles, high maintenance, inconsistent tension, and downtime can significantly impact your bottom line. Optimizing your web handling equipment is a direct path to smoother operations, reduced waste, and a better […]

The blown film extrusion industry faces a persistent challenge that has plagued manufacturers for decades: maintaining bubble alignment and film quality while meeting FDA compliance standards. Too many production lines still rely on cardboard, tape, and other improvised materials that compromise both safety and regulatory compliance. Pearl has engineered a definitive solution with Bubble Blockers—a […]

Understanding Plastics Production Processes In the world of plastics production, efficiency, quality, and safety are not just goals; they are requirements for success. Whether you are running a blown film extrusion line or managing a complex material converting process, every component and every step matters. A single weak link can compromise output, increase waste, and […]

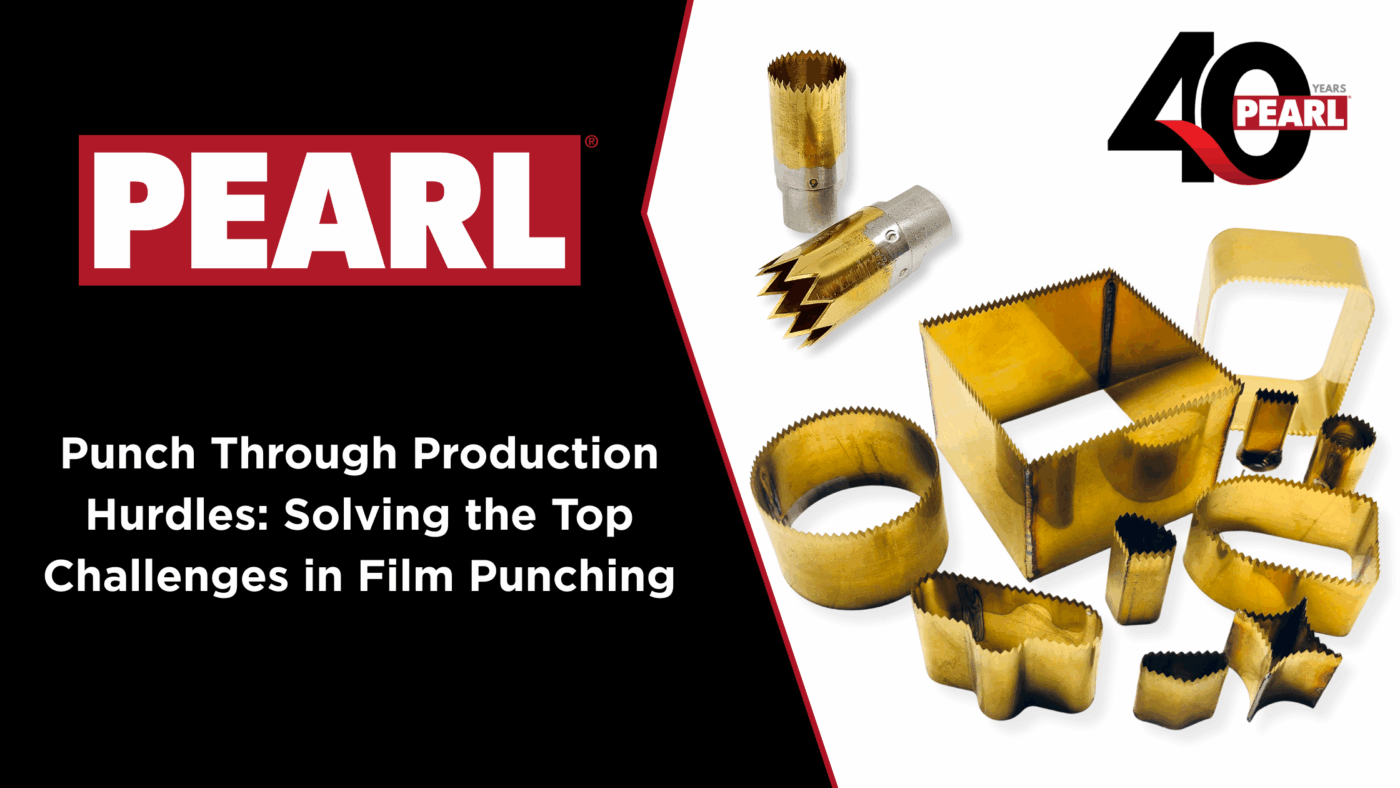

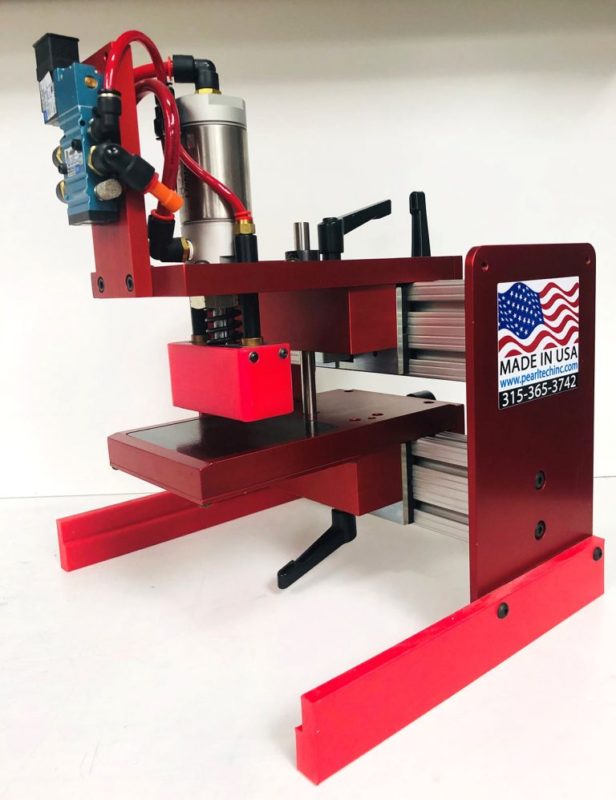

In the fast-paced world of modern manufacturing, film punching stands as a cornerstone process for creating holes, shapes, and perforations in a vast array of materials. From flexible packaging and agricultural liners to medical pouches and consumer goods, the speed, efficiency, and repeatability of hole punching are unmatched. However, when processes go wrong, this efficiency […]

Pearl Technologies, an EDGE Industrial Technologies brand, recently partnered with a leading producer of squeezable fruit pouches to optimize their manufacturing process. The Pearl customer utilizes six lines to convert rolls of flexible film into food-grade pouches, each equipped with eight zero-clearance units responsible for corner cropping. Challenge The existing punch units, manufactured by a […]

For manufacturers in flexible packaging, efficiency and adaptability are of the utmost importance. Pearl’s Flex Units are designed to meet these demands, offering unparalleled versatility to tackle multiple punching tasks with precision and ease. A Unit That Adapts to Your Needs Our Flex Units are engineered to excel in a variety of industries, from food […]

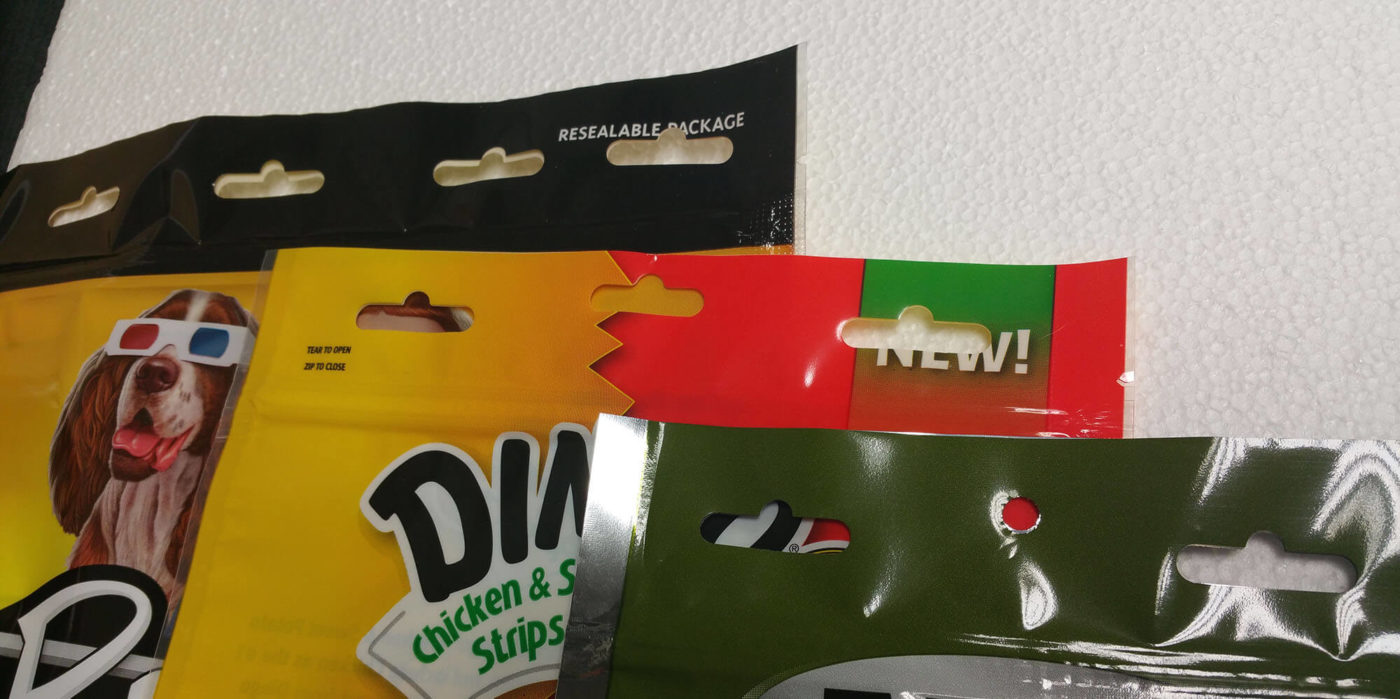

In the fast-paced world of packaging, every detail matters. This includes the tiny hanger holes and tabs that can make a big difference in product presentation and functionality. Whether you’re packaging snack bags, hardware items, or clothing, selecting the appropriate hanger hole punch is crucial for ensuring products stand out on the shelves and optimally […]

Pearl Technologies, a leader in offering the right technology and machinery to answer growing customer demand. There’s been few packaging innovations that have taken the world by storm like pouches have. Go to any zoo or park, and you’ll see plenty of children enjoying their pouch snack. And it’s not just food—the beverage industry has […]

Punches Make a Different in High-Quality and Consistent Packaging Operations Choosing the right punch for your flexible packaging operation is essential to ensuring quality and consistency in your product. Knowing how much you need to spend on punches to get the consistent quality you need is a key part of your business value proposition. Toothed […]